Introduction

In industries where metal surfaces are exposed to harsh conditions, scale, rust, and oxide layers can significantly impact performance and longevity. A Mechanical Descaler Machine offers an efficient, eco-friendly, and cost-effective solution to remove these unwanted layers, ensuring smooth and clean surfaces.

But how does it work? What industries benefit the most? And why should you consider one for your operations? Let’s dive in!

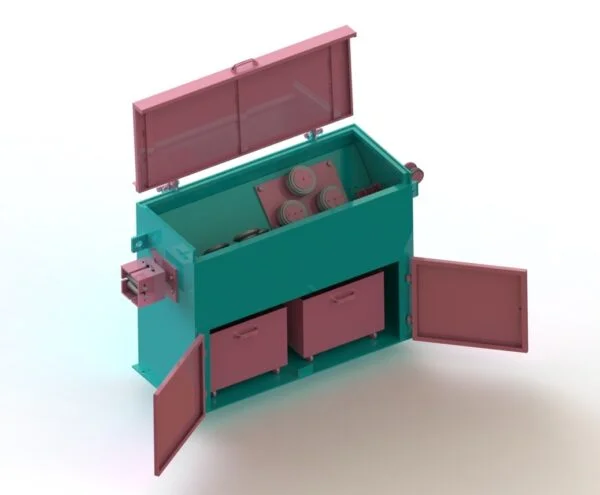

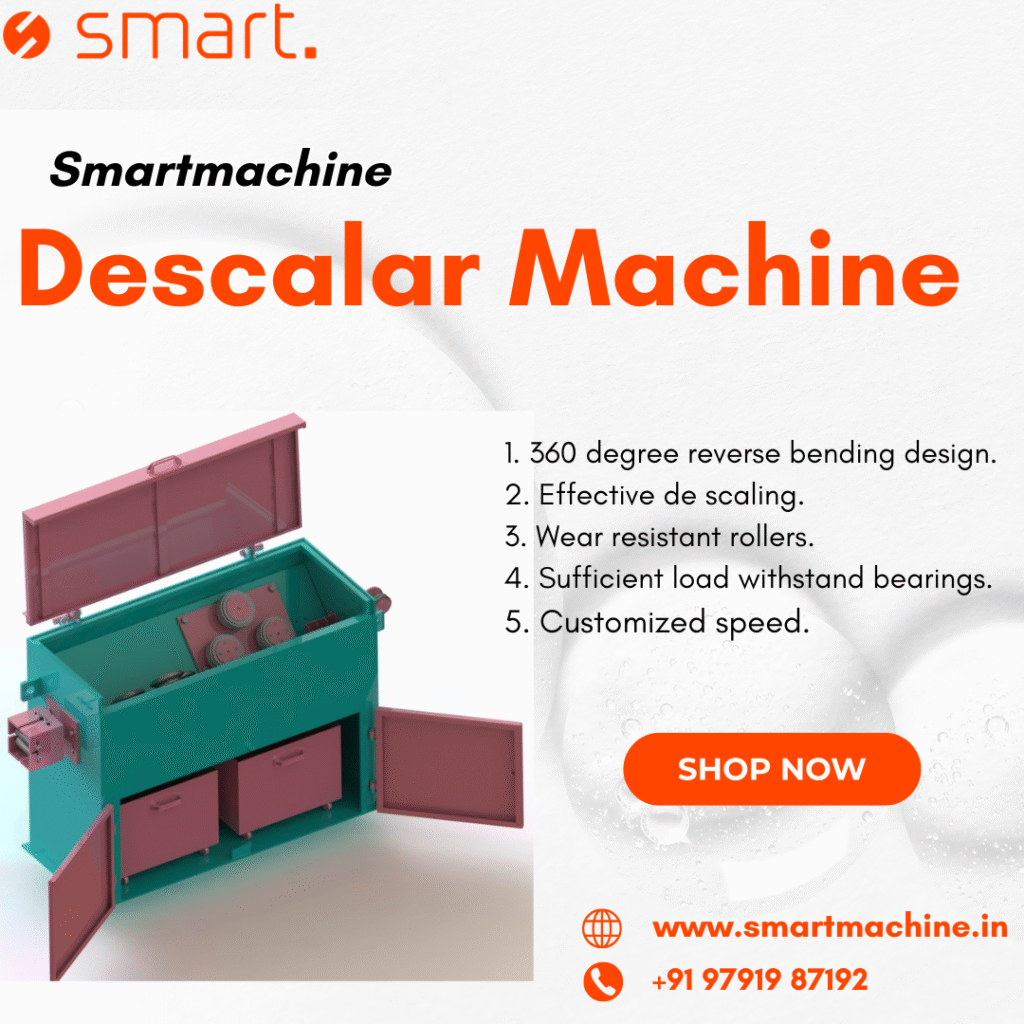

What is a Mechanical Descaler Machine?

A Mechanical Descaler Machine is an industrial device designed to remove scale, rust, and other surface contaminants from metal products (such as rods, wires, tubes, and sheets) using mechanical abrasion rather than chemical or thermal methods.

Key Components:

- Rotary Brushes or Abrasive Belts – For scrubbing off scale.

- High-Pressure Rollers or Shot Blasting Units – For deep cleaning.

- Adjustable Speed Motors – To control descaling intensity.

- Dust & Debris Extraction System – For a cleaner work environment.

How Does a Mechanical Descaler Work?

- Feeding the Material – The metal product is fed into the machine.

- Descaling Process – High-speed rotating brushes, abrasive rollers, or shot blasting remove surface impurities.

- Cleaning & Finishing – Loose particles are blown or vacuumed away, leaving a smooth surface.

- Output – The descaled material is ready for further processing (e.g., galvanizing, painting, or extrusion).

Benefits of Using a Mechanical Descaler Machine

✅ Eco-Friendly – No harmful chemicals, reducing environmental impact.

✅ Cost-Effective – Lower operational costs compared to acid pickling.

✅ High Efficiency – Removes scale uniformly in a single pass.

✅ Improved Product Quality – Enhances adhesion for coatings & extends metal life.

✅ Low Maintenance – Durable design with minimal downtime.

Industries That Use Mechanical Descalers

- Steel & Wire Manufacturing – For rods, bars, and coils.

- Automotive – Prepares metal parts for painting.

- Construction – Cleans rebars and structural steel.

- Pipe & Tube Production – Ensures smooth surfaces before coating.

- Metal Fabrication – Removes mill scale before welding or machining.

Mechanical vs. Chemical Descaling: Which is Better?

| Factor | Mechanical Descaling | Chemical Descaling |

| Process | Abrasion-based | Acid-based |

| Eco-Friendliness | No toxic waste | Hazardous chemicals |

| Speed | Fast & continuous | Slower, requires rinsing |

| Maintenance | Low | High (acid disposal) |

| Surface Finish | Uniform & controlled | Risk of over-etching |

For most industries, mechanical descaling is the preferred choice due to its efficiency and sustainability.

Choosing the Right Mechanical Descaler Machine

When selecting a descaler, consider:

🔹 Material Type (Steel, Aluminum, Copper, etc.)

🔹 Production Capacity (Batch vs. Continuous Processing)

🔹 Descaling Intensity (Light rust vs. heavy mill scale)

🔹 Automation Level (Manual vs. fully automated)

Conclusion

A Mechanical Descaler Machine is a game-changer for industries that rely on clean, high-quality metal surfaces. It offers a safer, faster, and greener alternative to traditional descaling methods, improving productivity and product longevity.

📞 Interested in integrating a descaler into your production line? Contact us today for expert recommendations!