Introduction

The wire manufacturing industry has evolved significantly with advanced technologies, and straight-line drawing machines have become indispensable for producing high-quality wires with precision and efficiency. As a leading straight-line drawing wire machine manufacturer, we understand how these machines revolutionize wire production across industries—from electrical cables to automotive components.

In this blog, we’ll explore:

✔ What straight line drawing machines are and how they work

✔ Key advantages over traditional wire drawing methods

✔ Applications in modern wire production

✔ How [Your Company Name] delivers cutting-edge straight-line drawing solutions

What is a Straight-Line Drawing Machine?

A straight-line drawing machine is an industrial system that reduces the diameter of metal wires (copper, aluminum, steel, etc.) by pulling them through a series of dies in a single, continuous process. Unlike wet drawing machines, which use lubricants, straight line machines often employ dry drawing techniques, making them ideal for certain wire types.

How It Works:

- Wire Feeding – Raw wire is fed into the machine.

- Multi-Stage Drawing – Passes through progressively smaller dies to achieve the desired thickness.

- Annealing (Optional) – Some machines integrate heat treatment for enhanced ductility.

- Take-Up System – Finished wire is coiled or spooled for further processing.

Why Modern Wire Manufacturing Relies on Straight Line Drawing Machines

1. Superior Precision & Consistency

- Produces wires with tight diameter tolerances (±0.01mm).

- Ensures uniform surface finish, critical for electronics and medical wires.

2. High-Speed Production

- Capable of speeds up to 1,500 m/min, outperforming traditional methods.

- Reduces production bottlenecks in large-scale wire manufacturing.

3. Energy & Cost Efficiency

- Lower power consumption compared to multi-stage wet drawing.

- Minimal lubricant use reduces operational costs and waste.

4. Flexibility for Various Materials

- Works with copper, aluminum, steel, and specialty alloys.

- Adjustable settings for fine wires (0.1mm) to thicker industrial cables (10mm+).

5. Reduced Wire Breakage & Downtime

- Advanced tension control prevents snapping during drawing.

- Automated threading systems minimizes manual intervention.

Key Applications in Modern Industries

| Industry | Use Case | Wire Type |

| Electrical | Power cables, winding wires | Copper, aluminum |

| Automotive | Tire bead wires, sensor cables | High-carbon steel |

| Construction | Reinforced concrete mesh, guy wires | Galvanized steel |

| Aerospace | Lightweight alloy wiring | Titanium, nickel alloys |

| Medical | Precision guidewires, implants | Stainless steel |

Innovations in Straight Line Drawing Technology

As a leading straight-line drawing wire machine manufacturer, we integrate the latest advancements:

✔ PLC-controlled automation for precise speed and tension adjustments.

✔ AI-driven defect detection to minimize waste.

✔ Energy-recovery systems for sustainable production.

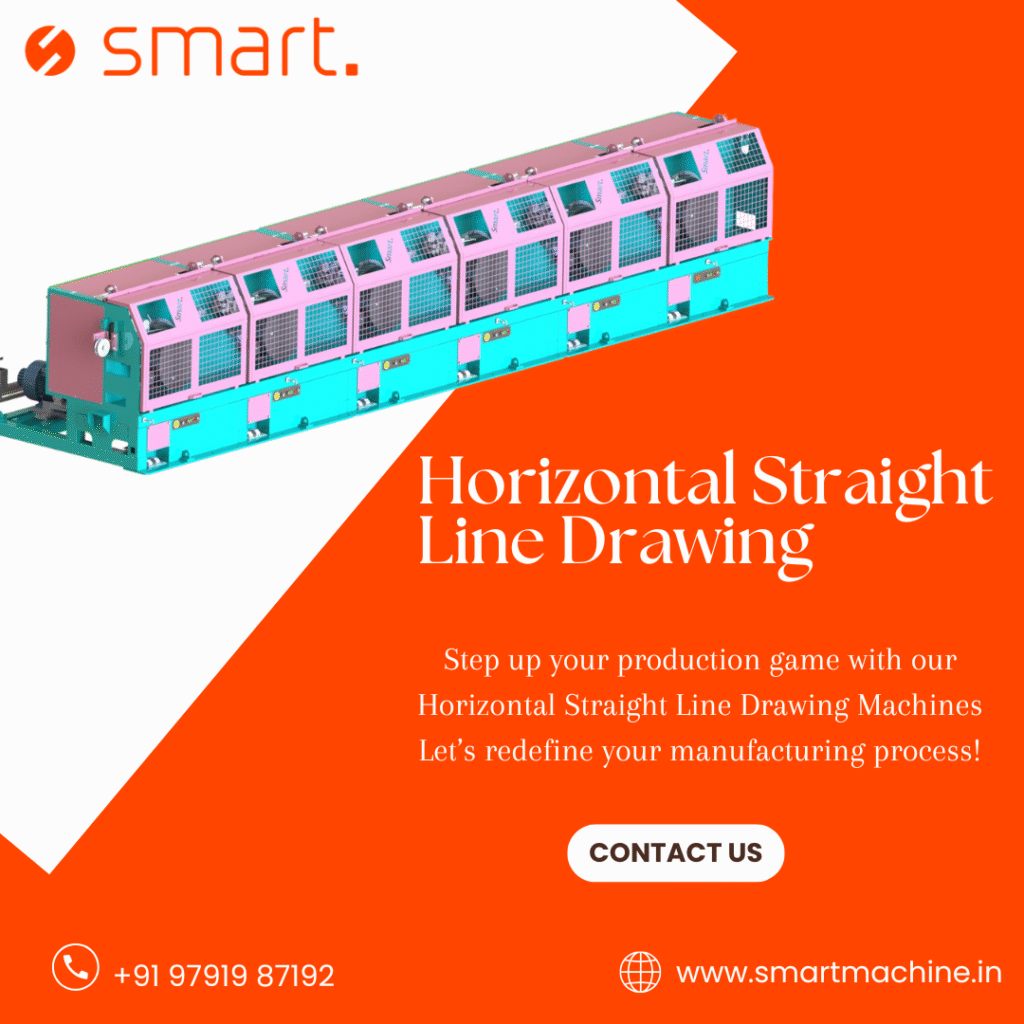

Why Choose Smart machine?

✅ Custom Solutions – Tailored machines for your wire specifications.

✅ Robust Build – Heavy-duty frames for 24/7 operations.

✅ Global Support – Installation, training, and maintenance services.

📞 Need a high-performance straight-line drawing machine? Contact us today!