When it comes to wire manufacturing and processing, precision and efficiency are crucial. The Horizontal Straight Line Drawing Machine is a game-changer in the industry, offering superior performance for producing high-quality wires with consistent diameters. But what makes this machine stand out from other wire drawing machines?

In this blog, we’ll explore the key features, benefits, and applications of the Horizontal Straight Line Drawing Machine and why it’s a preferred choice for wire manufacturers.

1. What is a Horizontal Straight Line Drawing Machine?

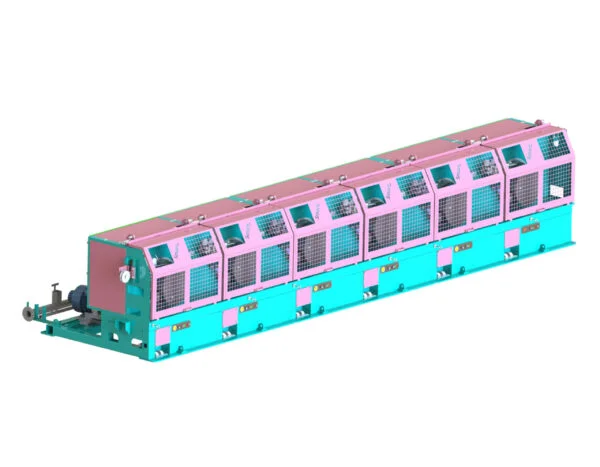

A Horizontal Straight Line Drawing Machine is an advanced wire drawing machine designed to reduce the diameter of metal wires (such as steel, copper, or aluminum) by pulling them through a series of dies. Unlike traditional drawing machines, this model operates in a horizontal, straight-line configuration, ensuring smoother operation and better wire quality.

Key Components:

- Drawing Capstan: Provides consistent pulling force.

- Wire Dies: Gradually reduce wire diameter.

- Lubrication System: Minimizes friction and wear.

- Tension Control: Ensures uniform wire thickness.

2. Why Choose a Horizontal Straight Line Drawing Machine Over Other Wire Drawing Machines?

✔ Higher Precision & Consistency

- Maintains tight tolerances for uniform wire diameter.

- Reduces wire breakage and defects.

✔ Improved Efficiency & Speed

- Continuous operation with minimal downtime.

- Handles high-speed drawing for bulk production.

✔ Space-Saving Design

- Horizontal layout requires less floor space compared to vertical machines.

- Easier to integrate into existing production lines.

✔ Lower Maintenance Costs

- Robust construction ensures longevity.

- Automated lubrication reduces manual intervention.

3. Applications of Horizontal Straight Line Drawing Machines

This wire drawing machine is widely used in industries that require precision-drawn wires, such as:

- Electrical & Cable Manufacturing (copper, aluminum wires)

- Automotive Industry (tire cords, spring wires)

- Construction & Reinforcement (steel wires for concrete)

- Fastener & Nail Production (high-tensile wires)

4. Advantages Over Traditional Wire Drawing Machines

| Feature | Horizontal Straight Line Machine | Vertical Drawing Machine | Block Drawing Machine |

| Space Efficiency | ✅ Compact, horizontal layout | ❌ Requires more height | ❌ Bulky design |

| Wire Quality | ✅ Smoother, more consistent output | ⚠️ Risk of twisting | ⚠️ Less precise |

| Production Speed | ✅ High-speed operation | ⚠️ Slower processing | ⚠️ Moderate speed |

| Maintenance | ✅ Low maintenance | ⚠️ Frequent adjustments | ⚠️ Higher wear & tear |

5. Conclusion: The Best Choice for Wire Drawing

The Horizontal Straight Line Drawing Machine outperforms traditional wire drawing machines in terms of:

✔ Precision & consistency

✔ Space-saving design

✔ High-speed production

✔ Lower operational costs

If you’re looking for a reliable, efficient, and high-performance wire drawing solution, this machine is the ideal investment for your business.

Interested in a Horizontal Straight Line Drawing Machine?

📞 Contact Us: +91 97919 87192

📧 Email: sales@samrtmachine.in

🌐 Website: www.smartmachine.in