In the world of cable manufacturing and insulation, precision isn’t just a goal—it’s a necessity. From heavy-duty industrial power cables to delicate fiber-optic communications lines, the quality of the protective coating can determine performance, safety, and service life. While electrostatic powder coating has long been recognized as a superior finishing method, the real game-changer lies in the technology used to apply it: electrostatic powder applicators. These sophisticated systems are revolutionizing how coatings are applied to cables, delivering unmatched precision, consistency, and durability.

What Are Electrostatic Powder Applicators?

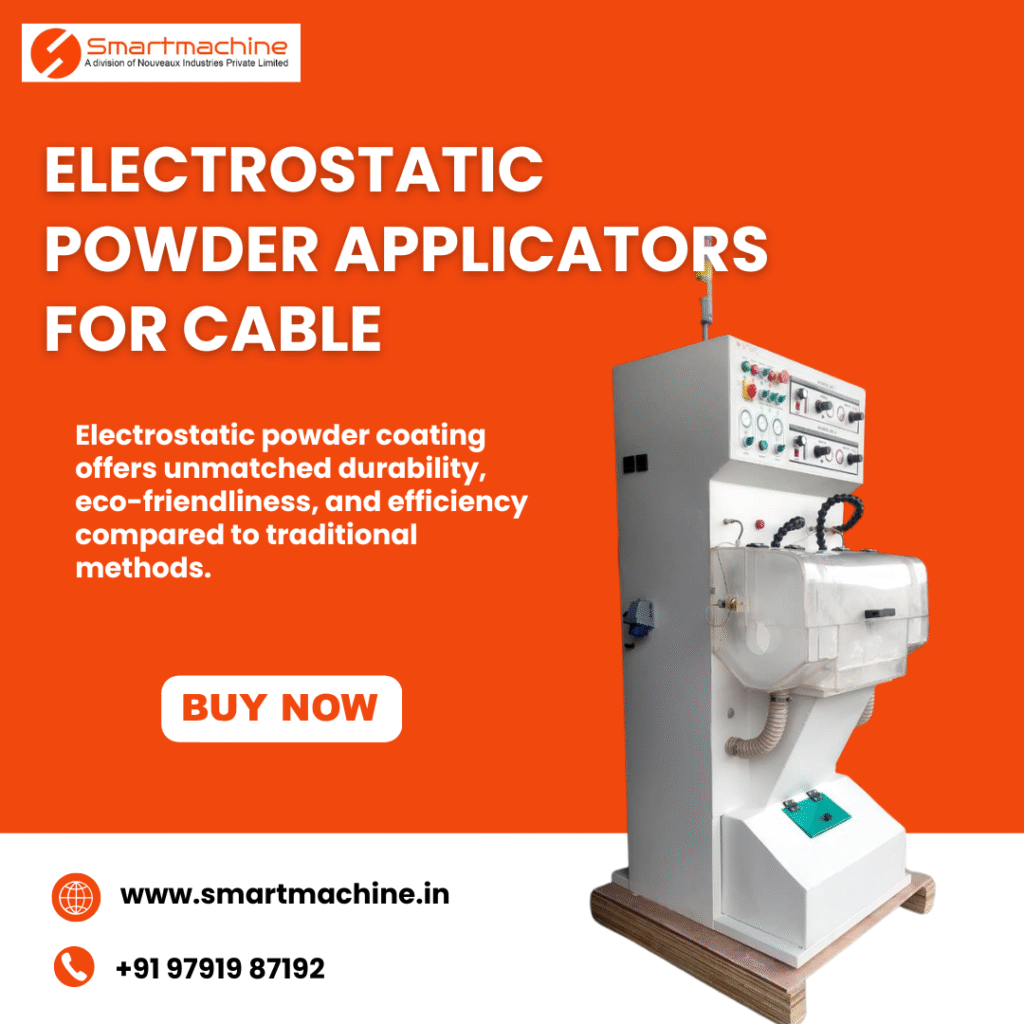

Electrostatic powder applicators are specialized devices designed to apply dry powder coatings to surfaces using electrostatic charge. In the context of cable manufacturing, these systems ensure that a uniform layer of powder adheres evenly to the cable’s surface—whether it’s a cable tray, conduit, or the cable itself. The process involves three key steps:

- Charging: The powder particles are electrostatically charged as they pass through the applicator gun.

- Attraction: The charged particles are attracted to the grounded cable surface, ensuring even coverage—even on complex geometries.

- Curing: The coated cable passes through a curing oven, where the powder melts and forms a continuous, resilient film.

This method eliminates many of the shortcomings of traditional liquid coatings, such as drips, uneven layers, or solvent evaporation issues.

How Electrostatic Applicators Enhance Precision

Precision is critical when coating cables, particularly those with irregular shapes or critical tolerances. Here’s how electrostatic applicators excel:

- Uniform Coverage: The electrostatic charge ensures that powder wraps evenly around the entire surface of the cable, including hard-to-reach areas like grooves or ridges. This eliminates thin spots or voids that could compromise protection.

- Controlled Thickness: Advanced applicators allow operators to fine-tune coating thickness with exceptional accuracy. This is especially important for cables used in high-voltage or extreme environments, where insulation integrity is non-negotiable.

- Minimal Overspray: Thanks to the targeted attraction between charged powder and the grounded substrate, waste is significantly reduced. This not only saves material but also ensures a cleaner, more efficient process.

Boosting Durability and Performance

The benefits of precision application extend directly to the durability and functionality of the coated cable:

- Superior Adhesion: Electrostatic application creates a strong mechanical bond between the powder and the cable surface. This results in a coating that is highly resistant to chipping, scratching, and abrasion—essential for cables installed in demanding settings like manufacturing plants or outdoor installations.

- Enhanced Corrosion Resistance: By forming a continuous, non-porous barrier, powder coatings applied with electrostatic systems provide excellent protection against moisture, chemicals, and UV exposure. This significantly extends the cable’s service life, even in harsh conditions.

- Improved Dielectric Strength: For cables requiring electrical insulation, the uniform thickness achieved through electrostatic application enhances dielectric performance, reducing the risk of short circuits or failures.

Applications Across Industries

The versatility of electrostatic powder applicators makes them suitable for a wide range of cable types and industries:

- Industrial Power Cables: Ensuring robust insulation for machinery, conveyor systems, and automation networks.

- Telecommunications and Fiber Optics: Protecting delicate internal fibers from environmental stressors.

- Automotive and Aerospace Wiring: Meeting stringent safety and durability standards for vehicle and aircraft cables.

- Solar and Renewable Energy Cables: Providing long-lasting UV and weather resistance for outdoor energy systems.

Why This Technology Is the Future

As industries increasingly prioritize sustainability, efficiency, and performance, electrostatic powder applicators are set to become the standard for cable coating. They align perfectly with modern manufacturing goals:

- Eco-Friendly: Powder coatings contain no solvents or VOCs (volatile organic compounds), making them an environmentally responsible choice.

- Cost-Effective: Reduced waste, lower energy requirements, and minimal rework contribute to lower total cost of ownership.

- Adaptable: New innovations in applicator design—such as automated control systems and IoT integration—are making the process smarter and more responsive than ever.

Conclusion

Electrostatic powder applicators represent more than just an upgrade in coating technology—they are a transformative tool for enhancing the precision, durability, and reliability of cables across countless applications. By ensuring uniform, consistent, and high-quality insulation, these systems help manufacturers meet the growing demands of modern infrastructure and technology.

Whether you’re designing the next generation of data center cables or reinforcing power networks for industrial use, investing in advanced electrostatic application technology isn’t just an option—it’s a strategic step toward superior performance and longevity.