In the world of wire production, efficiency, precision, and final product quality are paramount. The heart of achieving this lies in the drawing process, and for high-quality, fine-grade wire, nothing surpasses the capability of a High-Speed Wet Drawing Machine. These machines are the workhorses behind the wires that power our industries, from the copper in our electronics to the steel in our automobiles.

As global demand for superior wire grows, Indian manufacturers have emerged as trusted partners, engineering machines that combine advanced technology, robust construction, and exceptional value.

What is a High-Speed Wet Drawing Machine?

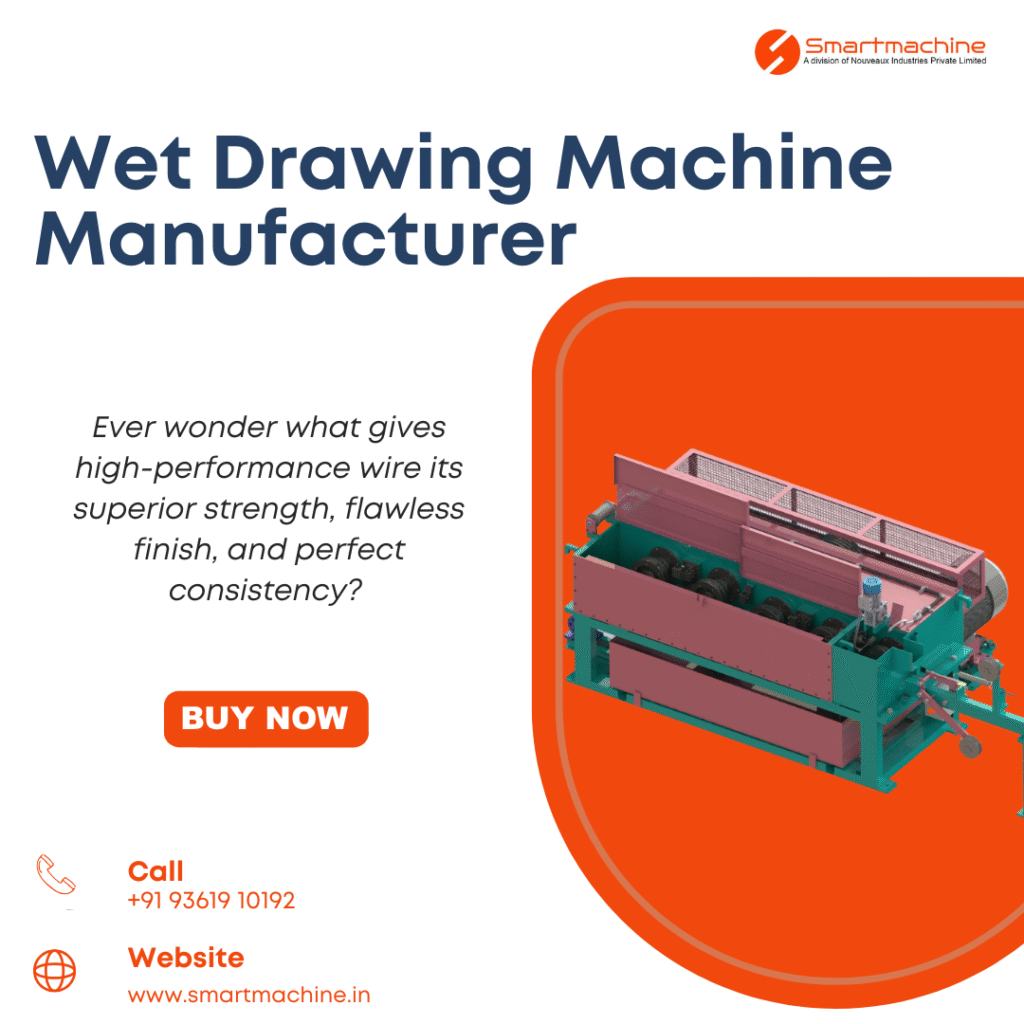

A wet drawing machine is designed to reduce the diameter of wire to precise, fine gauges by pulling it through a series of progressively smaller diamond or tungsten carbide dies. The “wet” process involves submerging the dies and the wire in a lubricating and cooling emulsion. This crucial feature allows for:

- Higher Drawing Speeds: Effective heat dissipation prevents annealing and allows the wire to be drawn at significantly higher speeds.

- Superior Surface Finish: The continuous lubricant flow results in a smooth, bright, and defect-free wire surface.

- Extended Die Life: Reduced friction and heat minimize wear and tear on the expensive drawing dies.

- Tighter Tolerances: Enables production of ultra-fine wires with consistent and precise diameters.

Key Features of Best-in-Class Indian-Made Machines

India’s leading manufacturers have perfected the design of these machines to meet international standards while catering to the specific needs of a global clientele. When you source from a reputable Indian maker, you can expect:

1. Unmatched Speed and Productivity:

Modern Indian-built machines operate at impressive speeds, often exceeding 1,500 meters per minute for non-ferrous wires, maximizing your output and ROI.

2. Robust and Durable Construction:

Built with high-grade materials and precision engineering, these machines are designed for 24/7 operation in demanding industrial environments, ensuring minimal downtime and long service life.

3. Precision Engineering for Superior Quality:

Features like in-line annealing systems, synchronized DC drives, and automatic tension control ensure the output wire has consistent tensile strength, diameter, and a brilliant finish.

4. Energy-Efficient Design:

With a focus on sustainability and cost-saving, manufacturers incorporate energy-efficient motors and optimized drive systems to reduce your operational costs.

5. User-Friendly Automation:

From intuitive PLC controls with touch-screen HMIs to automated pay-off and take-up systems, these machines are designed for easy operation and minimal manual intervention.

6. Customization and Flexibility:

Trusted manufacturers understand that one size does not fit all. They offer customizable solutions for various materials (copper, brass, aluminum, steel alloys), input/output wire sizes, and spooling configurations.

Applications: The Wire You Depend On

The wires produced by these high-performance machines are critical components in countless industries:

- Electrical & Electronics: Enamelled winding wires for transformers, motors, and coils.

- Automotive: Cable harness wires, tire bead wire, and other critical components.

- Telecommunications: Precision copper wires for data and telephone cables.

- Construction: Binding wires and other fine-gauge steel wires.

- Fastener Manufacturing: Wire for screws, nuts, and rivets.

Why Partner with an Indian Manufacturer?

Choosing an Indian manufacturer for your high-speed wet drawing machine is a strategic decision that offers significant advantages:

- World-Class Quality at Competitive Prices: You get technology and build quality on par with Western counterparts, but at a far more attractive price point, ensuring a faster return on investment.

- Strong Engineering Heritage: India boasts a deep pool of skilled engineers who design machines that are both technologically advanced and pragmatically built for real-world conditions.

- Proven Global Track Record: Indian-made wire drawing machines are exported and successfully operational worldwide, a testament to their reliability and performance.

- Comprehensive Service and Support: Leading manufacturers provide extensive after-sales support, including installation supervision, operator training, and readily available spare parts, ensuring your operations run smoothly.

Choosing the Right Manufacturing Partner

When selecting your supplier, look for:

- A Strong Portfolio: Request case studies and client references, particularly in your target material or industry.

- Technical Expertise: Engage with their engineering team to assess their ability to understand and solve your specific challenges.

- Quality Certifications: Ensure the company adheres to international quality management standards.

- After-Sales Commitment: Clarify the scope of their installation, training, and warranty services.