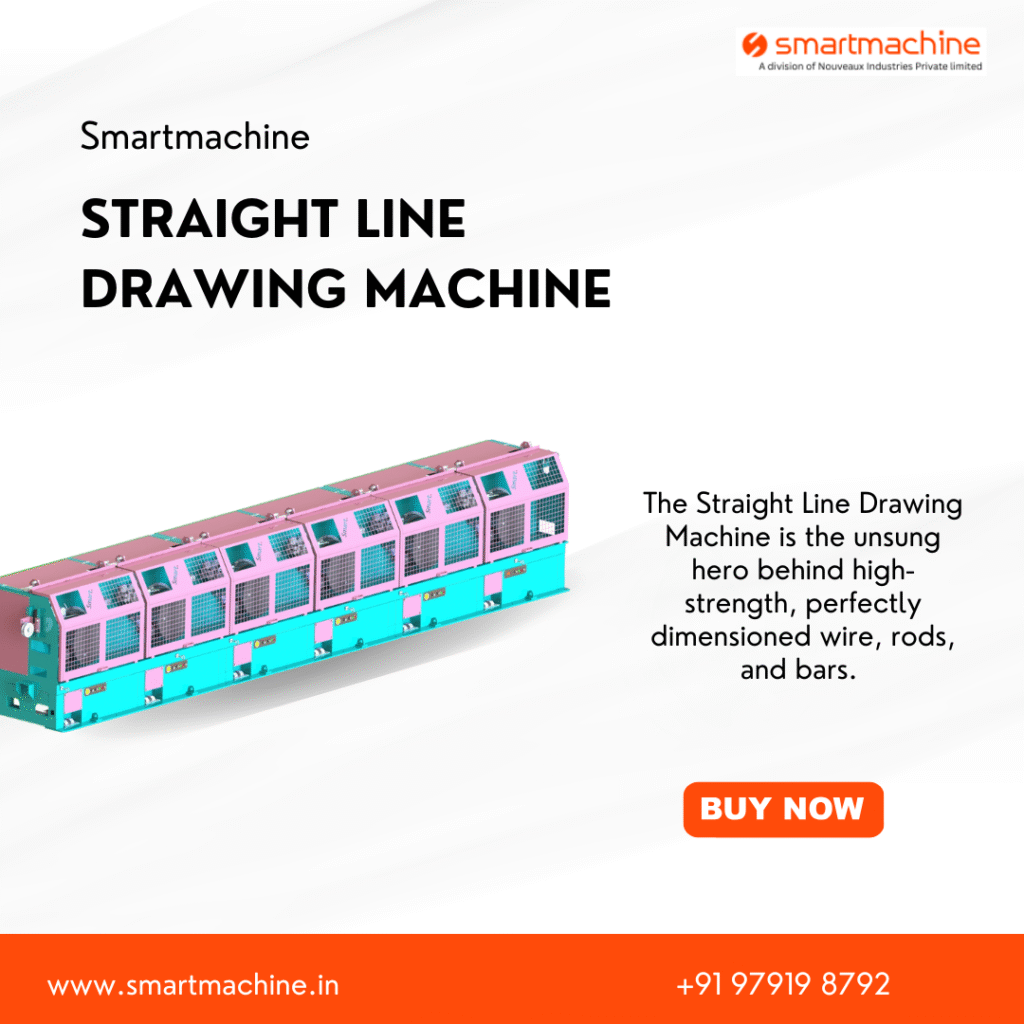

In the world of metal forming and manufacturing, precision, efficiency, and consistency are paramount. The straight line drawing machine is a cornerstone of modern metalworking, a powerful engine that transforms coiled or irregular metal into perfectly straight, consistent-diameter wire, rods, and bars.

But what exactly is this machine, and why is it so indispensable across countless industries? This guide delves into the inner workings of the straight line drawing machine, exploring its standout features, the tangible benefits it delivers, and its wide-ranging applications.

What is a Straight Line Drawing Machine?

A straight line drawing machine is an industrial system designed to pull (or “draw”) metal—typically steel, copper, aluminum, or other alloys—through a series of progressively smaller dies. This process cold-works the metal, reducing its cross-sectional area, improving its tensile strength, and enhancing its surface finish. Unlike continuous drawing systems that store finished product on a spool, the “straight line” configuration produces straight, cut-to-length pieces, ready for immediate use or further processing.

Key Features of a Modern Straight Line Drawing Machine

Today’s machines are engineered for high performance and reliability. Key features to look for include:

- Robust Construction: Built with a heavy-duty, vibration-resistant frame to ensure stability under high tensile loads and maintain precise alignment.

- Multi-Die Capability: Equipped with multiple drawing dies (often tungsten carbide or diamond), each slightly smaller than the last, to achieve the desired final diameter in a single, continuous pass.

- Powerful Drive System: Utilizes a high-torque, variable-speed DC or AC motor for smooth, controlled pulling power, allowing operators to fine-tune the drawing speed for different materials.

- Automatic Feeding & Handling: Advanced systems feature integrated decoilers, straighteners, and feeding mechanisms to automate the process from start to finish, minimizing manual labor.

- Precision Die Boxes: Engineered cooling and lubrication systems within the die boxes are crucial to reduce friction, manage heat, extend die life, and ensure a superior surface finish.

- PLC Control System: A programmable logic controller (PLC) allows for automated operation, preset recipes for different products, and real-time monitoring of parameters like speed, tension, and length.

- Cut-to-Length Unit: An integrated flying cut-off saw or shear automatically cuts the drawn product into precise, pre-set lengths.

Major Benefits of Using a Straight Line Drawing Machine

Investing in this technology offers manufacturers significant advantages:

- Superior Dimensional Accuracy: Produces wire, rod, and bar with exceptionally tight diameter tolerances and consistent cross-sectional geometry.

- Enhanced Mechanical Properties: The cold drawing process strain-hardens the metal, increasing its yield strength, tensile strength, and hardness.

- Excellent Surface Finish: Removes scale and imperfections, resulting in a smooth, clean, and often bright surface ready for plating, painting, or direct use.

- High Production Efficiency: Fully automated lines offer high throughput with minimal operator intervention, significantly boosting productivity and reducing labor costs.

- Material Versatility: Can be configured to process a wide range of ferrous and non-ferrous metals, including mild steel, stainless steel, copper, aluminum, and more.

- Production of Straight Lengths: The primary benefit over bull blocks: it produces straight, finished products ideal for applications like automotive parts, fasteners, and structural components.

Critical Industrial Applications

The straight line drawing machine is a workhorse in numerous sectors. Its output is fundamental to thousands of products we use every day.

- Automotive Industry: Manufacturing of precision piston rods, shock absorber rods, valve tappets, and fasteners that require high strength and exact dimensions.

- Fastener Production: Creating the raw wire for nuts, bolts, screws, rivets, and nails with consistent quality to ensure reliable threading and performance.

- Structural Components: Producing straight welding rods, low-relaxation prestressed concrete (PC) strands for construction, and sections for furniture.

- Electronics & Electrical: Drawing high-conductivity copper and aluminum wire for use in cables, motor windings, and electrical connectors.

- Aerospace & Defense: Manufacturing high-strength, high-precision alloy rods and wires for critical components where failure is not an option.

- Consumer Goods: Producing material for bicycle spokes, umbrella ribs, wire forms, and shopping cart handles.

Choosing the Right Machine for Your Needs

Selecting a straight line drawing machine depends on several factors:

- Material Type: What metal will you be drawing?

- Input Size: Starting diameter of your raw material (coil or bar).

- Output Size: Desired finished diameter and tolerance.

- Production Volume: Required output speed (meters per minute) and annual tonnage.

- End Product: Required final length and straightness.

Partnering with an experienced manufacturer is crucial to configure a system that optimizes productivity and ROI for your specific application.

Conclusion

The straight line drawing machine is more than just a piece of factory equipment; it is a transformative technology that enables the creation of high-performance metal components. By delivering unmatched precision, strength, and efficiency, it remains an indispensable asset in the manufacturing landscape, driving innovation and quality in products that shape our world.

Ready to explore how a straight line drawing machine can revolutionize your production line? Contact our experts today for a consultation and to find the perfect solution for your needs.