Take-up machines play a critical role in industries such as wire & cable, textiles, plastics, and metal processing. These machines ensure proper tension control, winding, and coiling of materials, enhancing production efficiency and product quality. Choosing the right take-up machine manufacturer is essential for seamless operations and long-term reliability.

This blog explores the importance of take-up machines, key features to look for in a manufacturer, and the industries that benefit from these advanced systems.

What is a Take-Up Machine?

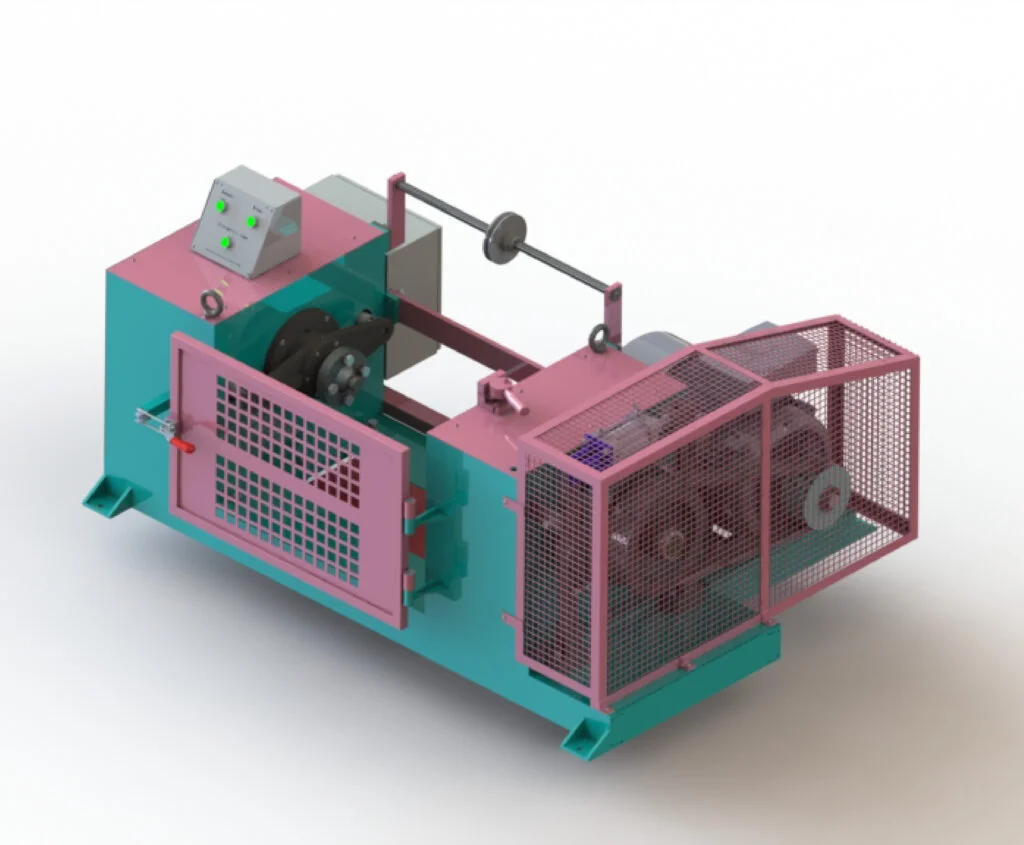

A take-up machine is an industrial device used to wind, coil, or collect materials (such as wires, cables, yarns, or sheets) under controlled tension. It ensures uniform winding, prevents material damage, and maintains consistent production speeds.

Common Types of Take-Up Machines:

- Wire & Cable Take-Up Machines – Used in extrusion lines for winding copper/aluminum wires, fiber optic cables, and power cables.

- Textile Take-Up Machines – Handle yarns, fabrics, and threads in spinning and weaving mills.

- Plastic Film Take-Up Systems – Used in blown film and cast film extrusion lines.

- Metal Coiling Machines – For rewinding steel strips, wires, and other metal products.

Key Features of a High-Quality Take-Up Machine

When selecting a take-up machine manufacturer, look for the following features:

✔ Precision Tension Control – Ensures smooth winding without overstretching or breaking materials.

✔ Adjustable Speed & Torque – Adapts to different production requirements.

✔ Durable Construction – Robust frames and corrosion-resistant components for long service life.

✔ Automation & Smart Controls – PLC-based systems for consistent performance and minimal manual intervention.

✔ Customizable Designs – Tailored solutions for specific industry needs.

Industries That Rely on Take-Up Machines

1. Wire & Cable Manufacturing

- Ensures precise winding of copper, aluminum, and fiber optic cables.

- Prevents tangling and maintains uniform tension in high-speed production.

2. Textile Industry

- Used in spinning, weaving, and knitting processes for consistent yarn collection.

- Reduces breakage and improves fabric quality.

3. Plastic & Packaging

- Handles plastic films, sheets, and laminates in extrusion lines.

- Maintains proper tension to avoid wrinkles or tears.

4. Metal Processing

- Coils steel strips, wires, and rods with precision.

- Used in wire drawing, rolling mills, and fastener production.

How to Choose the Right Take-Up Machine Manufacturer?

Selecting a reliable take-up machine manufacturer involves evaluating:

✅ Industry Experience – Look for manufacturers with expertise in your specific sector.

✅ Customization Options – Machines should be adaptable to different material types and production speeds.

✅ After-Sales Support – Warranty, maintenance services, and spare parts availability.

✅ Compliance & Certifications – Machines should meet international safety and quality standards (ISO, CE, UL).

✅ Customer Reviews & Case Studies – Check testimonials and real-world applications.

Why Partner with a Leading Take-Up Machine Manufacturer?

A trusted manufacturer provides:

- High-performance machines that reduce downtime and improve efficiency.

- Energy-efficient designs to lower operational costs.

- Innovative technology such as IoT-enabled monitoring for predictive maintenance.

- Global service networks for quick technical support.

Conclusion: Invest in Quality for Long-Term Success

Take-up machines are vital for maintaining production efficiency across multiple industries. By partnering with a reputable take-up machine manufacturer, businesses can ensure precision, durability, and optimal performance in their operations.

Looking for a high-quality take-up machine? Contact industry-leading manufacturers for customized solutions that meet your production needs!