In manufacturing and metalworking, achieving a flawless surface finish is crucial for both functionality and aesthetics. One of the most efficient tools for this purpose is the abrasive belt wire polishing machine, which delivers superior results compared to traditional manual methods.

This blog explores how abrasive belt polishing machines work, their key benefits, and why they’re essential for high-quality surface finishing in industries like automotive, aerospace, and metal fabrication.

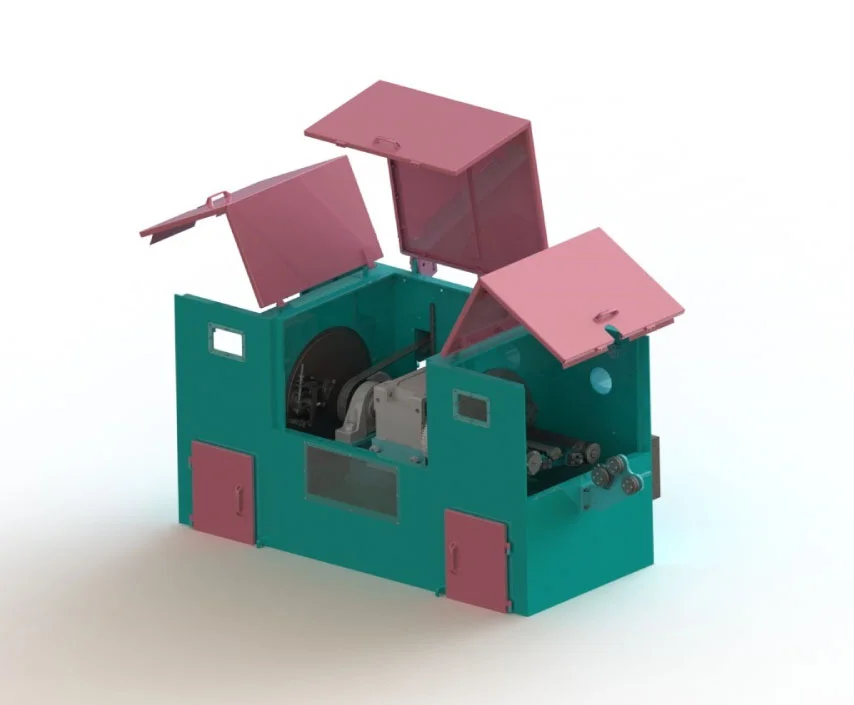

What Is an Abrasive Belt Wire Polishing Machine?

An abrasive belt wire polishing machine is a mechanized system that uses a continuous abrasive belt to grind, deburr, and polish metal wires, rods, and tubes. The machine operates by running the workpiece against a high-speed abrasive belt, ensuring consistent and precise finishing.

Key Components:

- Abrasive Belt – Made from aluminum oxide, silicon carbide, or zirconia for different finishes.

- Contact Wheel – Applies pressure to the workpiece for uniform material removal.

- Feed Mechanism – Automatically guides the wire through the polishing process.

- Dust Extraction System – Removes metal particles for a cleaner workspace.

How It Enhances Surface Finishing

1. Superior Consistency & Precision

Unlike manual polishing, which can lead to uneven finishes, an abrasive belt machine ensures:

✔ Uniform abrasion across the entire workpiece

✔ Repeatable results for high-volume production

✔ Controlled material removal without over-polishing

2. Faster Processing & Higher Efficiency

- Reduces polishing time by up to 70% compared to hand sanding.

- Handles large batches with automated feeding systems.

- Minimizes labor costs while increasing output.

3. Versatility for Different Materials & Finishes

These machines can polish a wide range of materials, including:

- Stainless steel, aluminum, copper, and titanium wires

- Round, flat, and shaped metal profiles

- Different grit belts (coarse to fine) for varying finishes (matte to mirror polish).

4. Improved Surface Quality & Durability

- Removes scratches, burrs, and oxidation effectively.

- Enhances corrosion resistance by creating a smoother surface.

- Prepares metal for coatings (plating, painting, or powder coating).

5. Cost-Effective & Low Maintenance

- Long-lasting abrasive belts reduce consumable costs.

- Minimal downtime with easy belt replacement.

- Energy-efficient compared to other polishing methods.

Industries That Benefit from Abrasive Belt Polishing

- Automotive – Polishing exhaust pipes, suspension wires, and decorative trims.

- Aerospace – Finishing precision aircraft components.

- Medical Devices – Smoothing surgical tools and implants.

- Jewelry & Decorative Metalwork – Achieving mirror finishes on wires and rods.

- Industrial Machinery – Deburring and polishing hydraulic/pneumatic components.

Choosing the Right Abrasive Belt Polishing Machine

When selecting a machine, consider:

✔ Belt Size & Speed – Determines polishing efficiency.

✔ Automation Level – Manual, semi-automatic, or fully automatic.

✔ Material Compatibility – Ensure it works with your metal type.

✔ Dust Management – Built-in extraction improves safety.

Conclusion

An abrasive belt wire polishing machine is a game-changer for industries demanding high-quality, efficient, and consistent surface finishing. By automating the polishing process, it enhances productivity, reduces costs, and delivers superior results compared to manual methods.

Looking to upgrade your polishing process? Consult with a machinery expert to find the best abrasive belt polisher for your needs!