In the foundational world of metal manufacturing, the humble wire is a critical component for countless industries—from construction and automotive to fasteners and electrical cabling. The transformation of bulky rod into precise, consistent wire begins with one essential machine: the Straight Line Drawing Machine. As India’s industrial capacity continues to expand, the demand for high-performance, reliable wire drawing technology has never been greater. At the forefront of meeting this demand is a dedicated cohort of engineering firms, establishing the nation as a hub for precision manufacturing.

This blog explores the vital role of the Straight Line Drawing Machine Manufacturer in India, the technological advancements defining the sector, and what to look for when choosing a manufacturing partner.

The Engine of Industry: What is a Straight Line Drawing Machine?

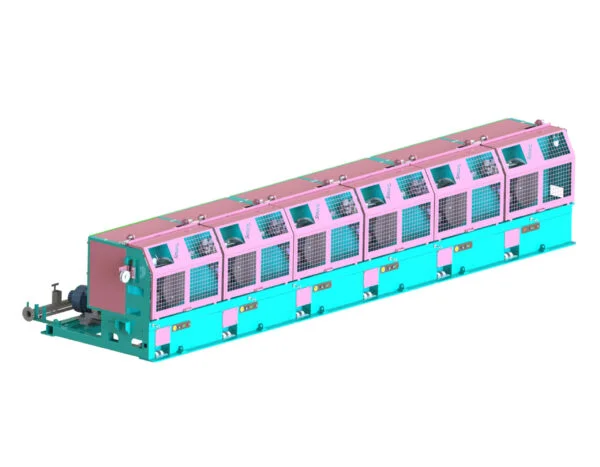

A Straight Line Drawing Machine is a sophisticated piece of industrial equipment designed to reduce the diameter of metal rods (typically steel, copper, or aluminum) by pulling them through a series of progressively smaller dies. Unlike cumulative or slip-type machines, a “straight line” configuration arranges the drawing blocks in a linear sequence. This design is renowned for its:

- High-Speed Production: Capable of exceptional output rates for medium to fine wire gauges.

- Superior Surface Finish: Produces wire with excellent dimensional accuracy and a smooth, clean surface.

- Operational Stability: The linear arrangement offers robust mechanical stability, reducing vibration and wear.

- Ease of Maintenance: Simplified layout allows for easier access to components for servicing and die changes.

Why “Made in India” is a Mark of Global Competence

Choosing an Indian manufacturer for such critical capital equipment is a strategic decision backed by significant advantages:

1. Cost-Effectiveness Without Compromise

Indian manufacturers offer a compelling value proposition, providing machinery that matches international quality standards at a significantly lower total cost of ownership. This is achieved through innovative engineering, local sourcing of components, and efficient production processes.

2. Deep Domain Expertise & Customization

With decades of experience serving both domestic and international markets, leading Indian manufacturers possess profound knowledge of diverse application needs—whether for tire bead wire, spring wire, CO2 welding wire, or prestressed concrete strand (PC strand). This expertise translates into an ability to customize machines for specific materials, final tensile strengths, and production environments.

3. Advanced Technology Integration

The modern Indian straight line drawing machine is a feat of engineering. Key technological features include:

- Variable Frequency Drive (VFD) Systems: For seamless speed control and energy efficiency.

- PLC-Based Automation: Ensuring consistent quality, precise synchronization, and easy operation.

- Patented Die Box Designs: For optimal lubrication and cooling, extending die life.

- In-Line Annealing Systems: Integrated heat treatment for intermediate stress relief, enabling the drawing of finer wires in a single pass.

4. Robust After-Sales & Technical Support

Proximity matters. A domestic manufacturer can provide rapid response for spare parts, on-ground technician support, and comprehensive training—minimizing downtime and ensuring your production line runs smoothly for years.

Key Considerations When Selecting Your Manufacturer

Partnering with the right manufacturer is crucial. Here are essential factors to evaluate:

- Proven Track Record & Portfolio: Examine their history, client list (especially in your target industry), and range of machine models (e.g., 7-block, 9-block, 11-block configurations).

- Focus on R&D: A manufacturer invested in research and development is one that will offer you future-proof technology.

- Quality of Core Components: Inquire about the source and brand of critical parts like motors, bearings, PLCs, and dies. Premium components ensure longevity.

- Comprehensive Service Offer: Look for partners who provide installation supervision, operator training, and a clear warranty and annual maintenance contract (AMC) structure.

The Future is Drawn Here

India’s position in the global wire and cable industry is strengthening. By investing in advanced, locally manufactured straight line drawing machines, wire producers not only empower their own competitive edge but also contribute to the nation’s vision of “Make in India” and “Aatmanirbhar Bharat” (Self-Reliant India).

The right machine is more than an equipment purchase; it’s the foundation for quality, efficiency, and growth. By choosing a reputable Straight Line Drawing Machine Manufacturer in India, you are choosing a partner committed to powering your precision and your productivity.