For the thriving automotive, fabrication, and heavy engineering industries of Tamilnadu—from the industrial belts of Chennai and Coimbatore to the growing hubs in Tiruppur and Hosur—a consistent, high-quality supply of welding consumables is the backbone of production. At the heart of this supply chain is the MIG Wire Production Line, a sophisticated symphony of metallurgy and precision engineering. But what exactly goes into manufacturing the spool of wire that feeds your welding torch?

Understanding this process is crucial, especially when selecting a MIG Wire Production Line manufacturer in Tamilnadu for your business or project. Let’s walk through the step-by-step journey of how standard MIG/MAG (Metal Inert Gas/Metal Active Gas) welding wire is made.

Step 1: Raw Material – The Steel Rod

The process begins with high-quality steel rod, typically sourced from trusted mills. The chemical composition (carbon, silicon, manganese, etc.) is carefully selected based on the final wire specification (e.g., ER70S-6 for mild steel). This rod, or “wire rod,” is the primary input and its quality dictates the final product’s performance.

Step 2: Primary Cleaning & Descaling

The wire rod has a layer of mill scale (iron oxide) and drawing lubricants from prior processing. It first passes through a mechanical descaling unit, often using abrasive brushes or bending techniques, to break off this scale. It may then go through an acid pickling or electrolytic cleaning bath for a chemically clean surface, essential for smooth drawing.

Step 3: The Core Process: Multi-Stage Wire Drawing

This is where the rod is reduced to its final diameter. It is pulled through a series of progressively smaller tungsten carbide or diamond dies in a wire drawing machine.

- Lubrication: Before each die, the wire is coated with a specialized lubricant (lime or phosphate coating) to reduce friction, prevent overheating, and ensure a smooth surface finish.

- Annealing: Between certain drawing stages (intermediate annealing) or after drawing to the final size (final annealing), the wire may pass through an electric or gas-fired annealing furnace. This process reheats the wire to relieve internal stresses, restore ductility, and control mechanical properties like tensile strength.

Step 4: Surface Treatment & Copper Coating

For most MIG wires, the next critical step is copper coating. The clean, drawn wire undergoes an electroplating or immersion process where a thin, uniform layer of copper is bonded to its surface.

- Purpose: The copper coating enhances electrical conductivity for a stable arc, improves corrosion resistance during storage, and aids in smooth feeding through the welding liner and gun.

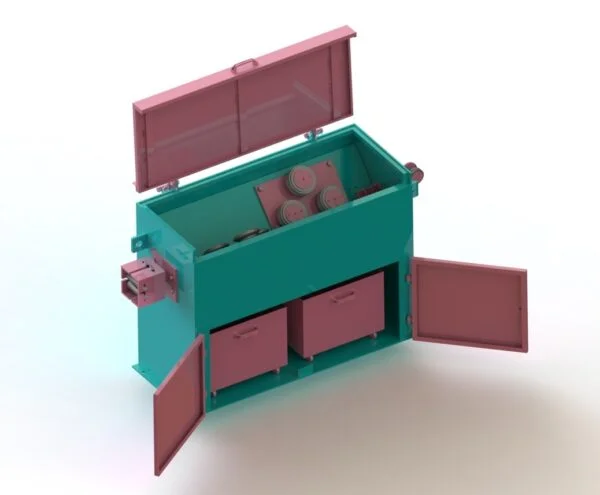

Step 5: Precision Spooling & Winding

The continuous wire is now fed into a high-speed spooling machine. This is a precision operation where the wire is wound uniformly onto plastic or metal spools (e.g., 5kg, 15kg, 200kg drums). Tension control is paramount here to avoid tangles, kinks, or cast (the natural curl of the wire off the spool), which directly impacts welding performance.

Step 6: Quality Control – The Non-Negotiable Step

At multiple stages, especially at the finish line, rigorous Quality Control (QC) is performed. This includes:

- Dimensional Checks: Ensuring consistent diameter using laser micrometers.

- Chemical Analysis: Spectrometry to verify alloy composition.

- Mechanical Testing: Checking tensile strength and elongation.

- Surface Inspection: Ensuring copper coating adherence and absence of defects.

- Run-Off Testing: Actual welding tests to verify arc stability, spatter levels, and bead appearance.

Step 7: Packaging & Dispatch

The final spools are packaged, labeled with classification, batch number, and date, and prepared for dispatch to distributors and end-users across Tamilnadu’s vast industrial sector.

Why Partner with a Reputed MIG Wire Production Line Manufacturer in Tamilnadu?

If you are in the business of producing welding consumables, the choice of your production line manufacturer is a strategic decision. Here’s what to look for in a MIG Wire Production Line manufacturer in Tamilnadu:

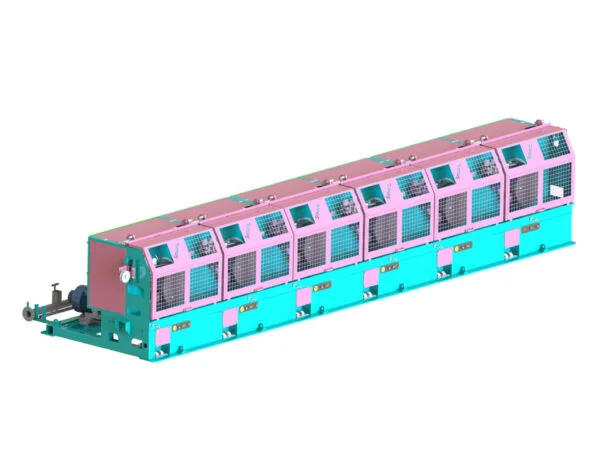

- Integrated Engineering Expertise: The best manufacturers don’t just supply machines; they provide a complete process line—integrating drawing machines, annealing furnaces, coating systems, and spoolers into one seamless, automated system.

- Customization for Local Demand: They understand the specific needs of Tamilnadu’s market—whether it’s wire for automotive component makers in Chennai, fabricators in Coimbatore, or shipyards in Tuticorin—and can tailor line specifications (wire grade, diameter range, spool type) accordingly.

- Focus on Quality & Consistency: A reputable manufacturer builds lines that ensure product consistency, which is the hallmark of a trusted MIG wire brand. Look for a partner whose engineering prioritizes precision tension control, uniform coating, and process stability.

- Turnkey Support: From installation and commissioning to operator training and maintenance support, a local manufacturer in Tamilnadu provides invaluable proximity for swift service, minimizing your downtime.

- Technological Edge: Seek out manufacturers who incorporate energy-efficient annealing technology, advanced digital controls for process monitoring, and robust mechanical design for high uptime.

Conclusion

The journey from a steel rod to a precision-wound spool of MIG wire is a marvel of modern industrial manufacturing. Each step in the production line is critical to ensuring the wire feeds flawlessly, arcs smoothly, and creates strong, clean welds.

For entrepreneurs and established businesses looking to set up or upgrade a wire production facility in the region, partnering with a knowledgeable and reliable MIG Wire Production Line manufacturer in Tamilnadu is the first weld in building a successful enterprise. It’s an investment in technology that guarantees you can meet the high-quality demands of Tamilnadu’s dynamic industrial landscape, one perfect spool at a time.

Ready to build your production capability? Connect with leading manufacturers who can guide you from concept to a fully operational, high-quality MIG wire production line.