In the competitive world of welding consumables, consistent wire quality isn’t just a preference—it’s an absolute necessity for precision welding performance and end-product reliability. At the heart of superior MIG (Metal Inert Gas) welding wire production lies a critical piece of technology: the High-Speed MIG Copper Coating Line. This advanced machinery represents the pinnacle of manufacturing excellence, and as a leading MIG Copper Coating Line manufacturer, we’re setting new standards in wire production technology.

The Critical Role of Copper Coating in MIG Welding Wire

Before diving into the machinery itself, it’s essential to understand why copper coating matters so much in welding wire production:

- Conductivity Enhancement: Copper coating improves electrical conductivity, ensuring smooth arc characteristics

- Corrosion Resistance: Protects the steel core from oxidation during storage and transport

- Feedability: Reduces friction in welding torches and liners for consistent wire feeding

- Contact Tip Longevity: Minimizes wear on welding equipment components

- Arc Stability: Promotes consistent welding performance with minimal spatter

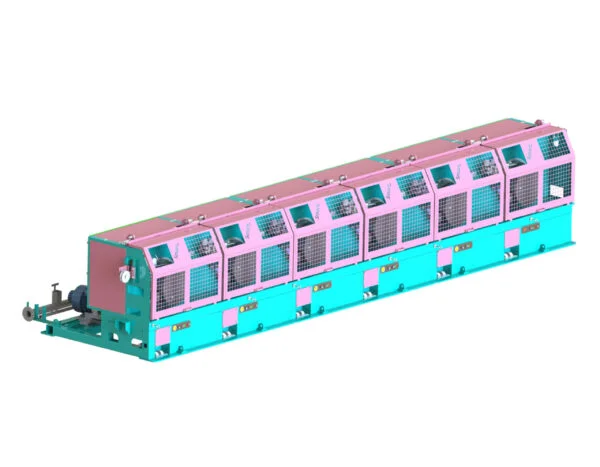

Introducing Our High-Speed MIG Copper Coating Line: Engineering Excellence

As an innovator in welding wire manufacturing technology, our High-Speed MIG Copper Coating Line incorporates groundbreaking features designed to deliver unprecedented quality and efficiency.

Core Technological Innovations

1. Precision Electroplating System

Our proprietary electroplating technology ensures uniform copper deposition with micron-level accuracy. Unlike conventional dipping methods, our electrochemical process guarantees:

- Consistent coating thickness (±0.2µm tolerance)

- 100% surface coverage without voids or pores

- Optimal copper adhesion for maximum durability

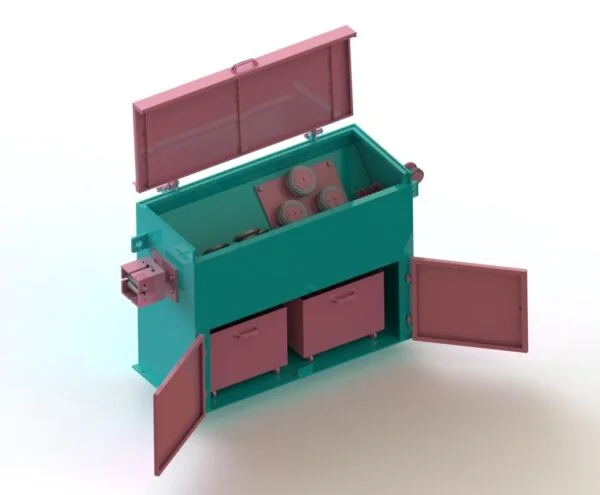

2. Advanced Pretreatment Module

Quality begins with surface preparation. Our line features:

- Multi-stage chemical cleaning for complete degreasing

- Electrolytic activation for perfect surface energy

- Rinse optimization to prevent contamination carryover

3. Patented Drying Technology

Moisture control is critical for corrosion prevention. Our system incorporates:

- Infrared pre-drying for surface moisture removal

- High-velocity hot air drying tunnels

- Moisture sensors with real-time feedback control

4. High-Speed Capability

Engineered for productivity without compromising quality:

- Operating speeds up to 600 meters/minute

- Continuous processing with automatic tension control

- Quick changeover between wire diameters

Quality Assurance Integration

What sets our line apart is the integrated quality monitoring system:

- In-Line Thickness Measurement: Laser-based continuous monitoring of copper deposition

- Surface Inspection: High-resolution cameras detect imperfections in real-time

- Conductivity Testing: Automated verification of electrical properties

- Adhesion Checking: On-line testing of coating bond strength

The Manufacturing Advantages: Why Our Technology Stands Out

Unmatched Consistency

Batch-to-batch variation is the enemy of welding performance. Our technology delivers:

- CV (Coefficient of Variation) of less than 3% in coating thickness

- Consistent surface roughness for predictable feedability

- Uniform electrical properties across entire production runs

Enhanced Productivity

- Higher Output: 30-40% increased production compared to conventional lines

- Reduced Downtime: Automated threading and tension management

- Lower Reject Rates: Real-time defect detection minimizes waste

- Energy Efficiency: Optimized power consumption per kilogram of output

Superior Final Product Characteristics

Wires produced on our High-Speed MIG Copper Coating Line demonstrate:

- Excellent Feedability: Smooth operation through all welding equipment

- Consistent Arc Characteristics: Stable welding performance with minimal spatter

- Extended Shelf Life: Enhanced corrosion resistance for longer storage

- Better Weld Quality: Improved mechanical properties in finished welds

Applications Across Industries

Our coating technology serves diverse welding requirements:

- Automotive Manufacturing: High-volume production of consistent welding wire

- Shipbuilding & Offshore: Corrosion-resistant wires for harsh environments

- Structural Steel Fabrication: Reliable wire for critical infrastructure projects

- Pipe Manufacturing: Consistent quality for automated welding processes

- General Fabrication: Versatile wire for diverse welding applications

Why Choose Our Technology as a MIG Copper Coating Line Manufacturer?

1. Decades of Specialization

With over [XX] years focused exclusively on welding wire production technology, we understand the nuanced requirements of copper coating like few others in the industry.

2. Customizable Solutions

While our standard lines offer exceptional performance, we specialize in:

- Custom configurations for specific wire types

- Integration with existing production facilities

- Scalable designs for future expansion

3. Comprehensive Support

Our commitment extends beyond equipment delivery:

- Installation and commissioning by expert engineers

- Comprehensive operator and maintenance training

- Ongoing technical support and spare parts availability

- Process optimization consulting services

4. Industry Compliance

All our systems are designed to meet or exceed:

- International welding standards (AWS, ISO, EN)

- Environmental and safety regulations

- Industry best practices for wire manufacturing

The Future of Wire Manufacturing: Smart Technology Integration

Looking forward, we’re pioneering Industry 4.0 integration in our coating lines:

- IoT Connectivity: Remote monitoring and diagnostics

- Predictive Maintenance: AI-driven component lifetime forecasting

- Data Analytics: Production optimization based on historical performance

- Energy Management: Smart power utilization for sustainability

Conclusion: Setting New Benchmarks in Wire Quality

In an industry where quality consistency directly translates to welding performance, structural integrity, and operational efficiency, settling for conventional coating technology is no longer an option. Our High-Speed MIG Copper Coating Line represents the convergence of precision engineering, advanced process control, and deep industry expertise.

As a dedicated MIG Copper Coating Line manufacturer, we’re not just selling equipment—we’re delivering a competitive advantage. Our technology ensures that every meter of wire produced meets the highest standards of quality, consistency, and performance.

Whether you’re establishing a new wire manufacturing facility or upgrading existing capacity, our High-Speed MIG Copper Coating Line offers the technological edge needed to excel in today’s demanding market.

Ready to transform your welding wire production quality?

Contact our engineering team today to discuss how our High-Speed MIG Copper Coating Line can deliver the consistent quality your customers demand and deserve. Let’s build the future of welding excellence—together.