In the high-stakes world of pipeline construction and heavy industrial fabrication, longevity and corrosion resistance are non-negotiable. Submerged Arc Welded (SAW) pipes form the arteries of global energy and infrastructure networks, and their endurance hinges on one critical process: copper coating. This precise application of a thin, uniform copper layer to the weld seam is a masterstroke of metallurgical protection, drastically enhancing corrosion resistance and extending pipeline service life by decades. At the forefront of this specialized technology stands Smartmachine, a pioneering SAW Copper Coating Line Manufacturer delivering advanced, automated solutions that set new benchmarks in quality, efficiency, and reliability.

Why Copper Coating is Indispensable for SAW Pipes

The weld seam of an SAW pipe is its most vulnerable point. Post-welding, this area is highly susceptible to accelerated corrosion due to microstructural changes. A precisely applied copper coating acts as a sacrificial layer and a robust barrier, offering:

- Superior Corrosion Resistance: Protects the weld seam from electrochemical and environmental corrosion, a critical factor for pipelines transporting oil, gas, and water.

- Enhanced Weld Longevity: Can extend the functional life of a pipeline section by 20-30 years, delivering an exceptional return on investment.

- Improved Cathodic Protection Compatibility: Ensures uniform current distribution in cathodic protection systems, a standard for buried and submerged pipelines.

- Cost-Efficiency: Prevents catastrophic failures and exorbitant repair/replacement costs, making it a essential preventive investment.

Smartmachine: Engineering the Future of Coating Precision

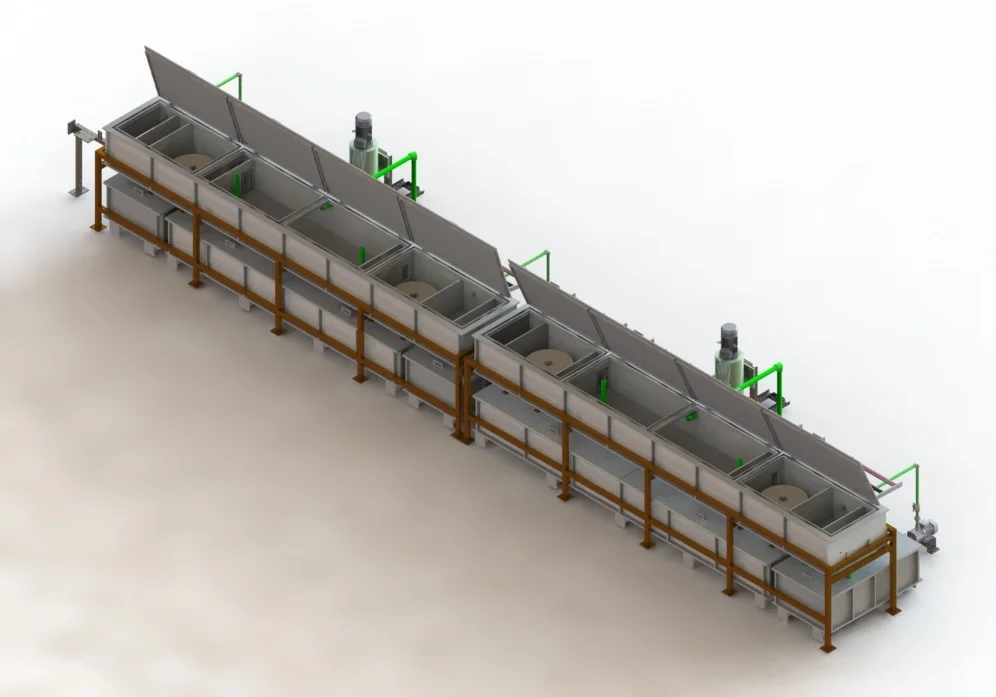

As a dedicated SAW Copper Coating Line Manufacturer, Smartmachine transcends standard equipment supply. We provide integrated, turnkey solutions built on deep process understanding and cutting-edge engineering. Our systems are designed for seamless integration into existing SAW pipe mills, transforming a critical manual or semi-automated process into a model of precision and repeatability.

Core Innovations of Our Advanced Copper Coating Lines

1. Unmatched Precision Application Technology

- Computer-Controlled Spray Systems: Our lines utilize advanced, programmable spray gun arrays that ensure a perfectly uniform copper layer thickness (typically 80-150 microns) across the entire weld seam circumference and length.

- Automated Thickness Monitoring: Integrated real-time sensors continuously measure coating thickness, allowing for instantaneous micro-adjustments to the application process, guaranteeing consistent quality.

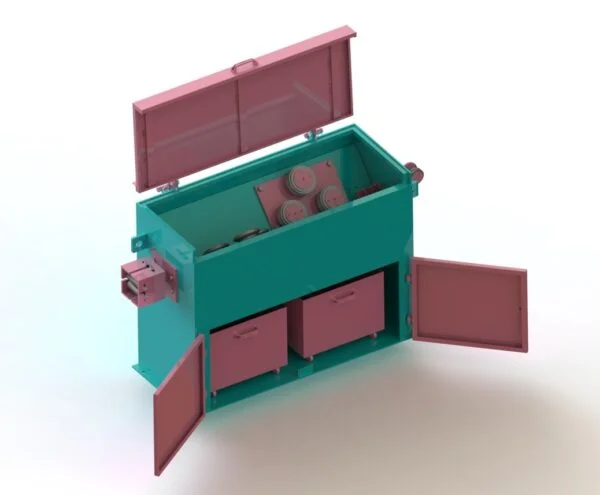

2. Fully Automated, Closed-Loop Process

- Seam Tracking & Guidance: Vision systems or laser guides automatically track the weld seam, ensuring the coating applicator maintains perfect alignment without manual intervention.

- Integrated Pre & Post-Treatment: The line can encompass automated surface cleaning/preparation stations and controlled drying/curing zones, creating a complete, in-line process flow.

- PLC-Based Control with HMI: A centralized, user-friendly Human-Machine Interface (HMI) allows operators to control every parameter—spray pressure, robot speed, pattern, and thickness—from a single panel, with recipe storage for different pipe specifications.

3. Built for Industrial Durability & Efficiency

- High-Speed Operation: Engineered to match the output of modern, high-speed SAW pipe mills without becoming a bottleneck.

- Robust Construction: Built with premium-grade materials to withstand the harsh, continuous-duty environment of a pipe mill.

- Minimal Waste & Eco-Conscious Design: Precise application drastically reduces copper solution overspray and waste, lowering material costs and environmental impact. Efficient filtration and recovery systems are available.

4. Custom-Engineered for Your Mill

We recognize that no two pipe mills are identical. As a solution-driven SAW Copper Coating Line Manufacturer, we specialize in:

- Line Customization: Adapting to your available floor space, pipe diameter range (from large-diameter transmission pipes to smaller distribution lines), and existing mill layout.

- Modular Design: Allowing for future upgrades or integration with other in-line processes.

- Comprehensive Support: Providing installation supervision, detailed operator training, and readily available technical support and spares.

The Smartmachine Difference: More Than a Machine

Choosing Smartmachine as your technology partner means investing in more than hardware; it’s an investment in peace of mind and competitive advantage.

- Deep Process Expertise: Our engineers understand the metallurgy and physics behind effective coating, ensuring our solutions address real-world production challenges.

- Proven ROI: Our automated lines deliver a rapid return through reduced material consumption, lower labor costs, eliminated rework, and the production of a higher-value, longer-lasting pipe product.

- Global Standards Compliance: Our systems help producers meet and exceed stringent international standards for pipeline corrosion protection (e.g., ISO, DNV, API).

Applications: Where Precision Coating is Critical

Smartmachine’s coating lines are essential for manufacturers serving:

- Oil & Gas Transmission Pipelines

- Water & Sewage Major Mains

- Structural Piling & Offshore Construction

- Industrial Process Piping

Conclusion: Elevate Your Product with Uncompromising Protection

In an industry where product integrity is paramount, the final step of copper coating cannot be an afterthought. It demands the precision, reliability, and intelligence of a dedicated, automated system.

Partner with Smartmachine, the innovative SAW Copper Coating Line Manufacturer, and transform this critical process from a potential weakness into your most consistent strength. Move beyond manual methods and embrace a future of flawless quality, operational efficiency, and superior product performance.

Ready to set a new standard in pipeline durability? Contact Smartmachine today to schedule a consultation and discover how our advanced copper coating solutions can be tailored to fortify your production line and your product’s future.